Our company introduced a new dye

2012.05.28 15:23

Brief introduction HA type reactive dyes:

1. HA type reactive dye is the company's new development of a group of high temperature and low alkali dyes, containing two or more than two active radicals, reaction is strong, be in slightly alkaline conditions and fiber occurred exclusively in the bonding reaction.

2. HA reactive dyes dyeing in low alkaline conditions, to maximize the control of the hydrolysis of the dye, improving the utilization of fixation rate and dye, to solve the sewage treatment by the traditional reactive dyes, alkali dosage of the problem. Can improve the dyeing fastness.

3. HA type reactive dyes in low alkali conditions on dyeing, dyeing rate is low, reducing the phenomenon of uneven dyeing.

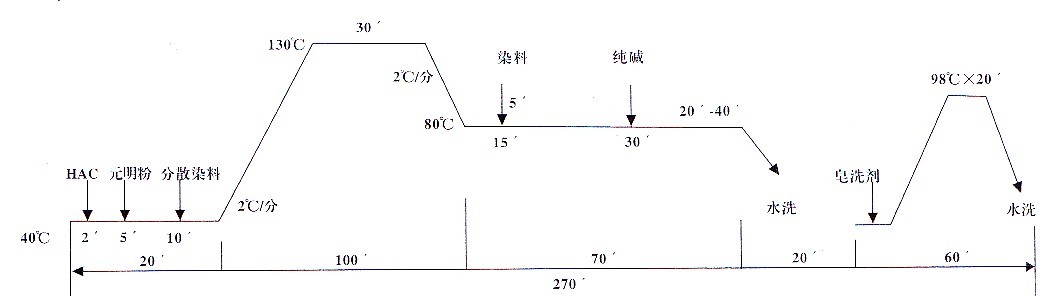

1. HA dye, in T/R, T/C, CVC polyester cotton blended fabric with disperse dyes can be together for one bath two step dyeing, and the fastness and conventional dyeing identical two bath two step process.(Soda ash dosage ratio of cotton increased by about 2G/L.)

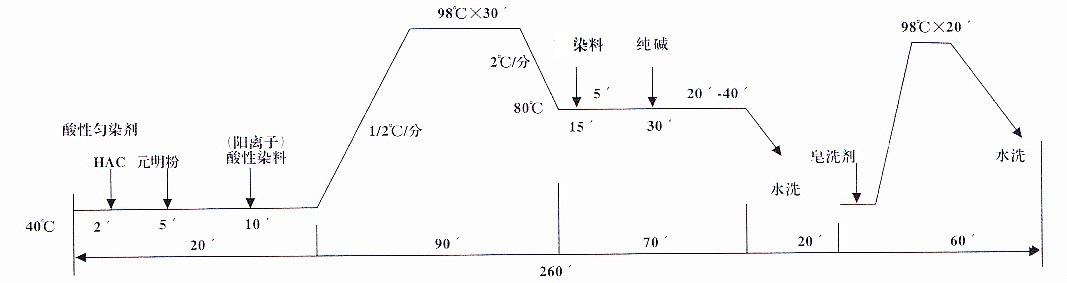

2. Dye,in N/R.C, A/R.C cotton (cotton nitrile) blended fabric with acid dyes (cationic dyes) with one bath two step dyeing. (Soda ash dosage ratio of cotton increased by about 2G/L.)

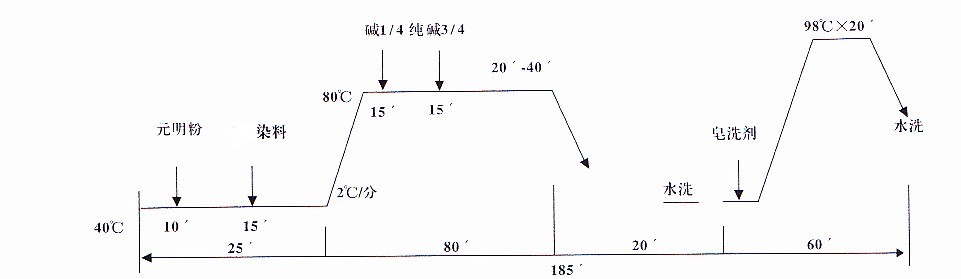

3.HA dye cotton, rayon dyeing process.

Advantage:

1. Compared to conventional combination may save sodium carbonate 80%-90%, and only need 1-3G/L.

2. Dyeing properties is good, process for dyeing a variety of colors, save 2-5 hours, high production efficiency; reduce the cost, simple operation, easy mastery.

3. Reduce the consumption of water,dyeing process with water only 2-3cylinder.

4. HA dye belonging to the environmental protection,COD than conventional reduced about 50%.

5. With a small amount of soda ash,fiber is not brittle damage, chromatin loss is small, not easy to produce alkali spot.

6. Excellent compatibility and dyeing stability, ensures the dyeing reproducibility and staining of the one time success rate, the basic no coloring no coloring phenomenon.

By Xiang Xiaoming