Progress with pigment for ink

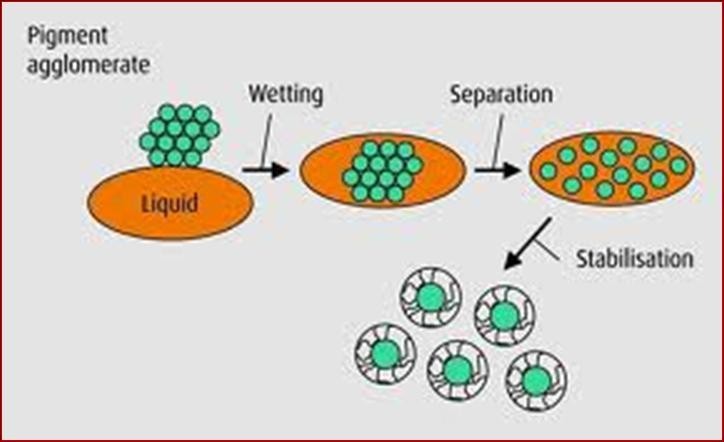

2013.09.09 17:22Pigment in the ink,paint,rubber,plastics,cosmetics,ink dispersion system needs to have a stable, homogeneous dispersion. Preparation of ink To solve the problem are: 1.Physical Specifications:Standard,to meet performance requirements of ink,having a suitable viscosity;surface tension;pH value;gravity;stability. 2.writing performance (for writing ink):to meet application performance requirements,with some lubrication;out of ink;crossed performance;pen performance;hat time. 3.inkjet Performance (inkjet ink):Meeting of the requirements can be sprayed. 4.fastness indicators: standard,to meet the water,light,weather stability,fastness requirements. 5.safety and environmental protection:the need to comply with EN71 and other safety and environmental standards,and so on. 6.matching:ink and nib;ink and printhead needed between each match. The general requirements for the performance of inkjet ink comprising: (1)can spray resistance:the performance of the two main indicators,namely the ink viscosity and surface tension;For continuous ink jet printer also requires conductivity. (2)Reliability:not block the nozzle;between the components of the inkjet ink and the ink jet ink jet head assembly and compatibility between (good match);has storage stability. (3)Image quality:Print quality is good (dot expansion permeability,optical density,print sharp edges);different print media in rapid fixation;water;Light;anti-friction. (4) Safety:non-toxic;non-flammable;low odor. Ink prepared to solve the problem The development of the recipe: First,make the appropriate ink viscosity,surface tension,pH,(for writing ink) is necessary to ensure the smooth writing pen does not leak,but also to protect the ink light,water,heat,cold,moisture and permeability;(right inkjet ink) In general,ink jet inks have a low viscosity,high surface tension,in order to ensure good flow properties and the droplet shape.Stability of the ink to be solved simultaneously to ensure longer saved by the ink is still not bad,does not appear stratification,precipitation,swimming and other phenomena;make sure the ink safety non-toxic,non-corrosive,but also to ensure that the ink and written,sprinklers match. Ink needs some stability?How should stabilize?Generally,the dispersion of the number of particles per unit volume for a long period of time (e.g.,several months or years) remain unchanged,then the dispersion is stable.Dispersion is essentially thermodynamics,kinetics unstable system,to ensure stable dispersion particles in the medium and easy. Organic pigment (ink) in the ink stability requirements To the pigment dispersion:Colloid stability: no particle growth,with a variety of other components of the ink compatibility,high purity,particle size is small (less than 150 nm),and has low viscosity,high surface tension. Wetting,grinding and dispersion,stable and-paste the manufacturing process Dispersant adsorbed on the pigment surface,adsorption and desorption is a dynamic process?Disadvantages: 1.large viscosity, 2.surface tension and 3.other components of the ink may not match? 4.the ink system is unstable? With a surface active agent or polymeric dispersing agents for aqueous ink pigments dispersed disadvantages: 1.If necessary to increase chroma increase in pigment concentration,the viscosity will increase. 3.increased foaming,make ink (print) stability deteriorates. The Way to solve the above problems The pigment particle surface by a chemical reaction directly into the polar group,so no dispersant pigment particles dispersed in water can be themselves?Self-dispersible pigment dispersion

One technological development

How to make (micro) nanoscale pigment particles uniformly and stably dispersed in the ink pigment ink system ----- key technology

One of the trends:resin+additives+grinding,particle surface modification from dispersing,

SDP Self Dispersing Pigments

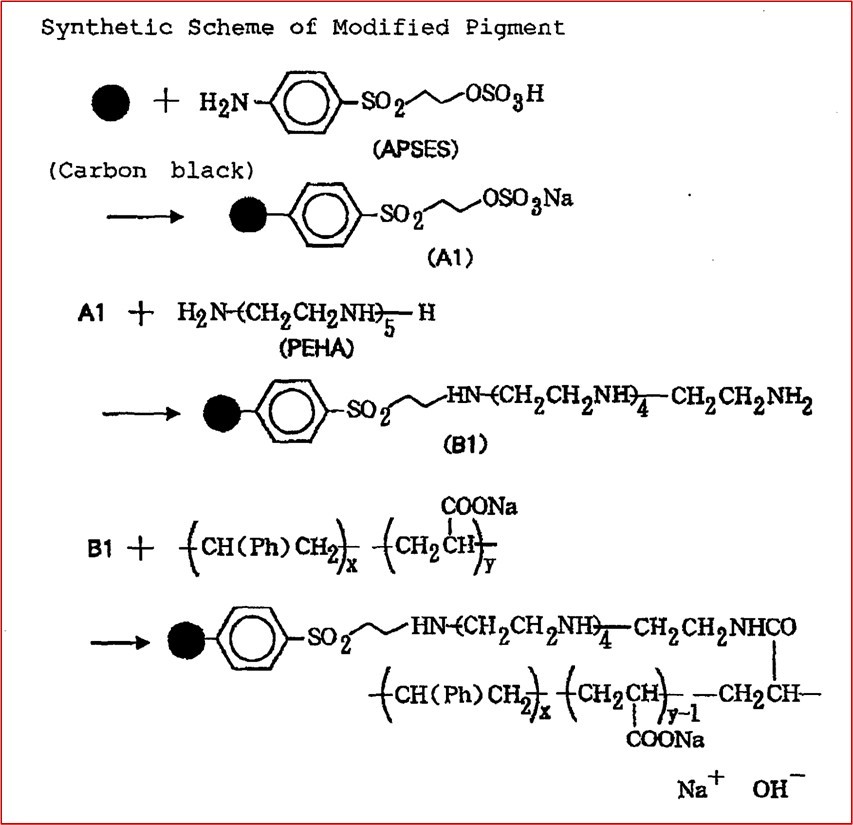

Through a specific chemical reaction,the surface modification of the pigment particles into a hydrophilic group,producing a self-dispersing pigment.

Major companies are trying to develop their own technologies.Such as:

- Degussa:Diels-Alder reaction

- Rohm and Haas:persulfate oxidation

- DuPont:ozone oxidation

- Cabot:diazo reaction

- Many other companies:Direct sulfonation

SDP advantages:

• The physical properties of the pigment dispersion

- High surface tension (~70mN/m)

- Viscosity (<2.5mpa.s solids content of 10%)

- High colloidal stability

- High-purity (covalent bond,a dispersant,a resin)

• Ink

- Recipe flexible (good compatibility)

- A dispersant (no foaming)

- Excellent reliability (writing,printing stability)

Modified Method:

R = COOH

SO3H

Polymers

Mixed

Ultrafiltration to remove reaction by-products,excess salt and unreacted starting material and soluble impurities through the membrane away from the surface modified pigment,the pigment dispersion to obtain high purity.

SDP has a low viscosity,high surface tension,high dispersion stability characteristics suitable for the preparation of a variety of water-based inks,to meet the desired end use performance requirements,is to solve the domestic ink technology foundation.

By Betty