Active dye used in the techique of active (discharge

2012.07.18 13:00Discharge prints also be called as sculpture. It is the pringting process to print mill base which can eliminate ground colour to produce white or colourful pattern on the dyed fabric. During the printing course, we should print the mill base which could destory the ground colour on the ground colour fabric, and after drying we should use colour die which contains discharging agent or the colour die could resistence to discharging agent at the same time to print. When post-processing, ground colour die in the printing will achromatic because of damage, and form white patterns or colourful patterns because of colourful die, which is called discharge. People pay more attention to discharge prints because its patterns are more meticulous and reality, have rich layers, strong colour contrast,clear outline, and plump colour light. Different farbic choose different chemical discharge agents. Discharge printing can be used in cloths and finished clothing.

Discharge resist printing of cotton fabric: we could use the die could be discharged or thevinyl sulfone reactive black dyeto dye the grounding, after drying them, we should use Shi Zhao printing process to overprint the black grounding andif we adopt rolling-the law method, the die will be uneasy to solidficate. To overprint,dry, decate, on the unset balck grounding and promote it to developing colour at the same time, the black will turn to black in red easily.

1.Procedure

Dyeing grounding colour——printing——drying——steaming——baking——rinsing——soaping——rinsing——drying

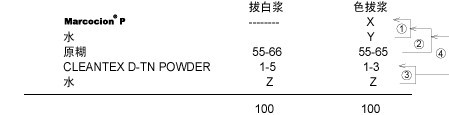

2.Mill base confect:

① Original paste confect:

Temperature of the water to dissolve urea proper to be 80℃ to dispel the possibility when urea dissloving to absorb heat .

When we are confecting original paste, we should add water to discharging agent EMVATEX DK-TN, and after mixing them, lay them aside for a while to make the paste eapand ,dissolve them fully and it will be translucent.

② Discharge prints mill base confect.

3.Process requirement

Before rinsing or soaping the fabric, we should eliminte float color and residual elixir and use the process of cold rinsing——warm rinsing——soaping——warm rinsing to wash,and the soaping should be adequate to guarteen the effects

temperature time

steaming 102-105 ℃ 8 -10min

baking 160℃ 3min

soaping >95℃ 3 - 5min

4.Attention!

After printing the fabric must be drying fully.

Through the course you can change the baking and steaming process according to fabric, government or other factors.Before changing, you should test it to guarteen the effect and put into use.

We should eliminte float color before soaping, and adopt the second rinsing if it is necessary to prevent staining.

Duing discharge paste preparation, the helping puu agent should be added in mill baseat last.

By Lu Saisai